English Curriculum Training

Six Step Pattern of Ministry

English Child Evangelism

Sowing Seed of Success

Turkey Moringa

Other Moringa Projects

|

|

home>>sowing seeds of success >>introduction>> moringa >>processing

Moringa the Miracle Tree - Processing

Moringa is one the greatest gifts which

Nature bestowed on man - this was known to the ancient world

and they regarded the tree as a “Cure-all Tree”.

They also saw the Moringa tree as an “Elixir of long

life”, “the Tree of Immortality”, “the

Tree of Life”, “the Never Die Tree”, “the

Miracle Tree" and “Mother’s best friend”.

|

Other common names for Moringa are Drumstick tree (referring

to the large drumstick shaped pods) Horse-radish tree, Benolive

tree (referring to the oil that can be squeezed out of the

seeds)

|

The Africa Bureau of Children's Discipleship, our African charity, is looking to establish

three small Moringa Processing plants in Malawi, Tanzania

and Uganda before we embark on our major commercial project

on a large portion of land in DR Congo. This vision has now exteded into earthquake struck Turkey.

|

|

STEP 1- Harvesting:

Moringa can be grown intensively with no irrigation

and small amounts of fertilizer. Harvesting the leaves every

75 days—four crops in a year with around 100 tons of

green matter per hectare the first year, and 57 tons per hectare

the second year.

If however the Moringa plantation is irrigated

and fertilized harvesting can be achieved every 35 days—nine

crops per year—with a total yield of 650 tons of green

matter per hectare. This yield can be consistent from the

same plants for seven years.

|

|

|

-

The Moringa leaves are

transported to the Processing Plant where they are first

washed in large buckets or pots in well or catchment water.

-

The second wash is done in BioSand filtered water.

This particular type of filter is an adaptation of the traditional slow sand filter, which has been used for community water treatment for almost 200 years. The BSF is smaller and adapted for intermittent use, making it most suitable for households, typically around five people. The filter body, or the outside of the filter (also known as the filter container), is commonly made of concrete.

Photographes compliments of Shape Lives Foundation

|

|

|

| |

The BSF removes almost all of the dirt and pathogens from water up to 99%! The BSF is a great low-tech answer to purify drinking water and is used in communities all over the world

In countries where people don't have running water in their home and have to use pond or standing water, a BioSand Filter is a great technology to give people clean, safe water that doesn't make them sick. For countries following a natural disaster where their water systems are compromised this could be of great help.

The Biolayer and the sand in the filter help remove the pathogens that make people sick.

|

|

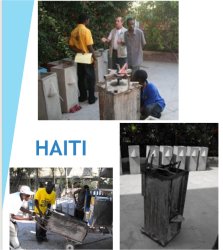

Since 2008 United Caribbean Trust has worked with organisations like 'Clean Water for Haiti' to introduce the BioSand Water Filtration system into Haiti. This is because we, like other International organizations such as Ohorizons, feel it is the most accessible, affordable (Less than US $100), easy to use, easy to maintain, and most durable design. |

Step 3 - Picking:

Hats, masks, gloves and over coats are worn

to comply with good food hygeine standards.

The washed Moringa leaves are then removed

from the twigs. (These can be chopped into 10cm pieces and

fed to cattle, sheep or goats)

Once removed the leaves are collected and

placed in a large bowl.

Photographs compliments of Shape

Lives Foundation |

|

|

Step 4 - Drying:

The leaves are now placed in the drying

trays in the shade for 2 - 3 days.

The leaves are shifted around a few times

per day to ensure a circulation of air.

The drying area must be rodent free.

Photographs compliments of Shape

Lives Foundation

|

Step 5 - Pounding:

While hand grinding is still widely used it

is slow, time and labor intensive and often produces an inconsistent

Moringa leaf powder.

It is still used however at the stage before

grinding.

Photographs compliments of Shape

Lives Foundation |

|

|

Step 6 - Grinding:

A flour grinding mill can be

used attached to a small engine to work the machine.

Photographs compliments of Shape

Lives Foundation

|

|

This is the latest video from Shape

Lives Moringa (Moringa ) Farm showing all the various stages of processing

Moringa and the processing methods. This various video shows

the experience gained in processing Moringa for the past

years and adopting the best hygiene practices to ensure

quality.

CLICK

to view English Video

|

SOWING SEEDS OF SUCCESS - MORINGA CURRICULUM

|

|

|